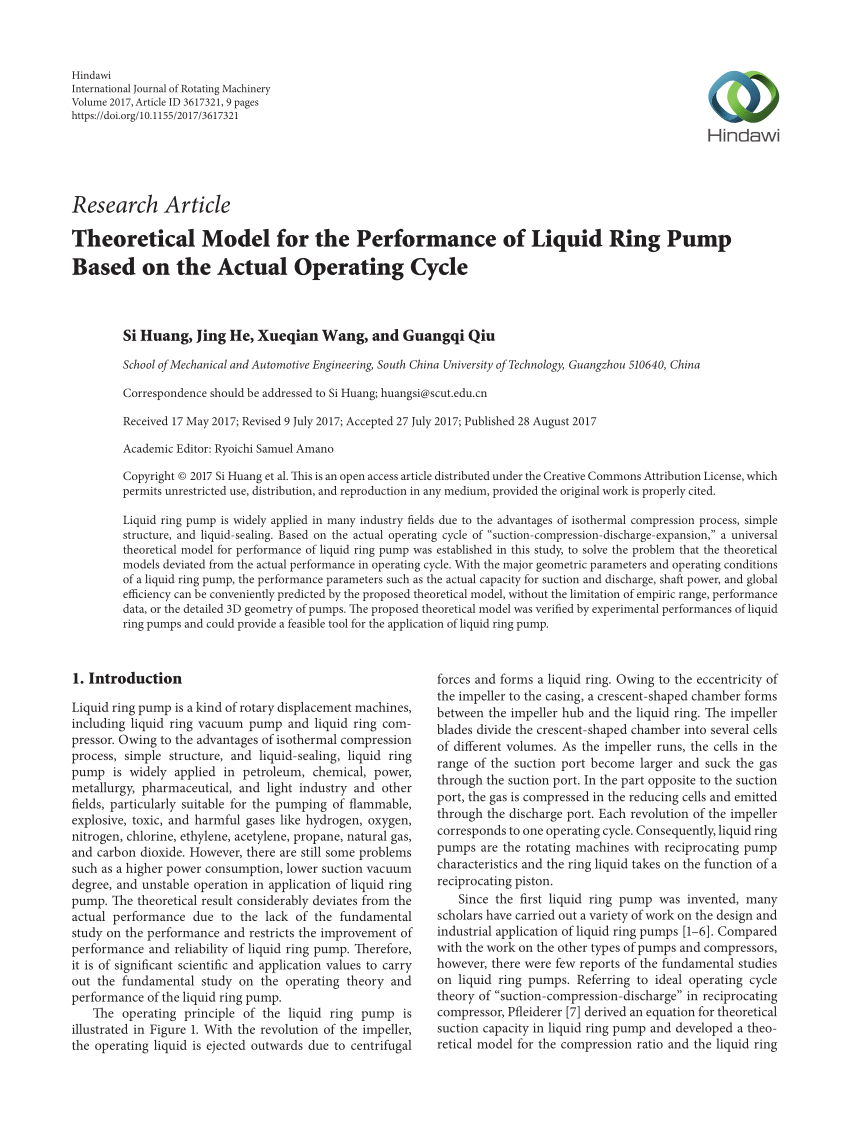

Based on the actual operating cycle of suction compression discharge expansion a universal theoretical model for performance of liquid ring pump was established in this study to solve the problem that the theoretical models deviated.

Liquid ring compressor working principle pdf.

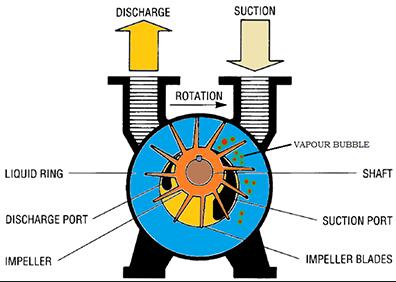

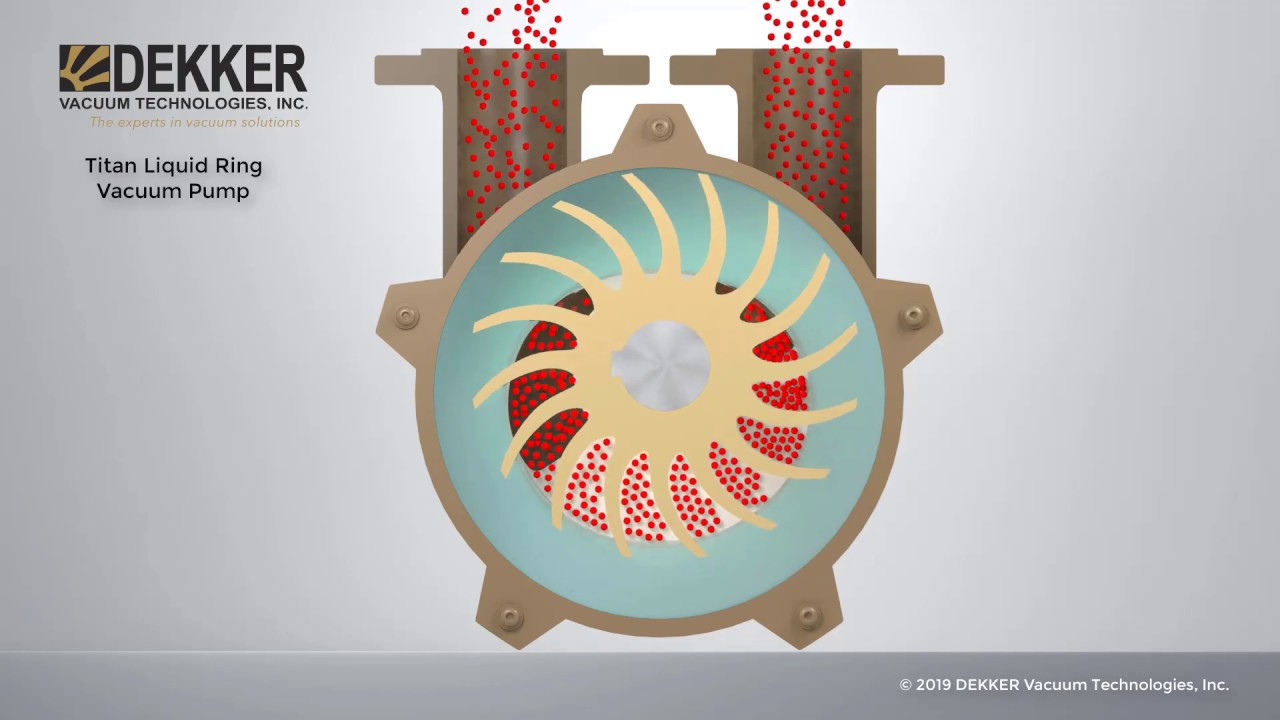

They are typically used as a vacuum pump but can also be used as a gas compressor the function of a liquid ring pump is similar to a rotary vane pump with the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression chamber seal.

A liquid ring pump is a rotating positive displacement pump.

Liquid ring pump is widely applied in many industry fields due to the advantages of isothermal compression process simple structure and liquid sealing.

Flare gazı geri kazanımın ünitesinin en önemli ekipmanı.

Principle of a liquid ring gas pump 20 5 4 3 1 21 2 7 6.

Compressor liquid ring compressor radial flow compressor axial flow compressor gas ring compressor.

The nash compressor is simple with only one moving part that is a rugged balanced rotor requiring no internal lubrication.

They operate according to the positive displacement principle.

Liquid ring vacuum pump type ensival moret vrn liquid ring vacuum pump for demanding applications the vrn liquid ring vacuum pump range mainly present in the fertilizer industry has been designed as the best solution for vacuum applications where wet or extremely humid and slightly contaminated gases are ingested.

In these machines a liquid is made to act as a piston.

Inside a nash liquid ring compressor.

The working principle of a liquid ring compressor.

The liquid compressant is represented in the below model by the grid patterned area.

Gas and liquid flow passages 13 working ranges 15 operating characteristics 17 operating modes 36.

I think that document will be ok for every single person in search of compressor and its types.

Liquid ring compressors are commonly used in features processes because of their ability to use any kind of service liquids.

Liquid ring compressors require a fluid preferably water as an auxiliary or service liquid.

This feature makes the liquid ring compressors unique for special applications where process contamination is prohibit.

The process gas enters the compressor through its conical distributor that is fixed to the compressor front cover.